By: Mutmainah Septiani, Traction Energy Asia

“Global Warming” has become quite a catchphrase nowadays. The word “global” makes it an important issue, since it concerns the whole world and not just specific countries. It certainly leaves us wondering: what causes global warning? And what harm does it do?

Global warming is basically caused by the high concentration of Greenhouse Gases (GHG)―Carbon Dioxide (CO2) and Methane―which are released into the air and cause the average temperature of the atmosphere and sea to increase. GHG are not only harmful to our health, but also disastrous for Earth’s ecosystems. So, what are Indonesia’s efforts to overcome this?

In 2015, through his speech at UNFCCC COP 21 in Paris, President Joko Widodo stated Indonesia’s commitment to the global action and pledged to reduce GHG emissions by 29% in 2030. Most of the efforts made by the Indonesian Government are projected from mitigation actions in land and energy sectors, with new and renewable energy (NRE) portion targeted at 23% of total national energy mix by 2025 and 31% by 2050. These targets are contained in the Presidential Regulation No. 22 of 2017 on National Energy Plan (RUEN).

Following up the RUEN, the Indonesian Government issued a number of policies for the purpose of achieving the targets. One of them is the policy on the use of Biodiesel produced from Crude Palm Oil (CPO) for the transportation sector.

The Indonesian Government set out the implementation and utilization of biodiesel gradually in several stages. The first stage is the use of B15, which is a mixture of 15% biodiesel and 85% diesel/fossil fuel, followed by the use of B20 (20% CPO) in next stage, then B30 (30% CPO), and so on until it reaches B100 (green fuel). The use of palm oil commodity as feedstock for Biodiesel production is expected to meet the following purposes:

- Achieving national energy resilience

- Reducing consumptions and imports of fossil fuels

- Creating added value for the palm oil industry from upstream to downstream

- Contributing to the reduction of GHG emissions in the energy sector.

However, biodiesel production process has created a polemic, considering it mainly uses palm oil, which is deemed not eco-friendly. This has become a concern for the environmental activists. Biodiesel combustion emissions are indeed lower compared to those of fossil fuels, but the carbon footprint of the entire biodiesel production process could be higher. In other words, the biodiesel policy has become a paradox, as the biodiesel is expected to reduce GHG emissions but on the other hand it produces more GHG emissions from the production process.

Study on Biodiesel Production Emissions

Traction Energy Asia (Traction) conducted a study using the Life Cycle Analysis (LCA) methodology on the production of CPO-based biodiesel. The purpose of the study is to find out whether the use of biodiesel will produce more GHG emissions compared to the use of fossil fuels or the other way around. The scope of this study starts from the Land Use Change (LUC) stage to B20 blending stage. Thus, the LCA will show the total emissions generated from the biodiesel production practices.

The data used in the study was obtained from the sustainability report of several palm oil companies. In addition, Traction research team also conducted a field survey to collect samples and verify the data of smallholders. For the survey, Traction chose two regencies in each of two provinces: Siak and Pelalawan in Riau and Sanggau and Sintang in West Kalimantan. The two provinces were chosen because, according to the data from the Directorate General of Plantations in 2018, they are among the five largest palm-oil-producing provinces in Indonesia.

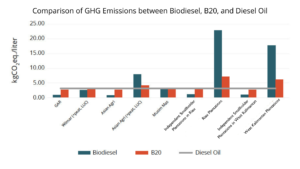

The large volume of GHG emissions is practically caused by differences in the initial function of the land, the type and amount of fertilizer used in the farm, the process of distributing fresh fruit bunches (FFB) to the palm oil mills (POM), and palm oil mill effluent (POME) management practices in the POM. The use of peatlands as independent smallholders’ palm oil plantations results in higher emissions from independent smallholders compared to plantation companies, as shown in the following chart:

According to the study, total GHG emissions from LUC sector to biodiesel ranges from 2.67 kg CO2eq/L of B20 to 7.09 kg CO2eq/L of B20. Initially, emissions generated from plantation companies were higher. However, since the company productivity―as the denominator in the calculation―is also high, the emissions per ton of FFB is lower. Another differentiating factor is the type of soil: mineral or peat. Biodiesel produced by plantations on peatlands results in a very high increase of GHG emissions, up to 6.08 kg CO2eq/L of B20 in West Kalimantan and 7.09 kg CO2eq/L B20 in Riau. However, if it is assumed that there is no palm oil development on peatlands and all land development is carried out on mineral soil, total emissions generated by independent smallholders and plantation companies are not that much different. Therefore, cultivation on peatlands is concluded to be the major contributor to the final GHG emissions from biodiesel.

Aside from LUC sector, the study finds that GHG emissions from POME in POM also contributes to total emissions. The use of methane capture facility has proved to be effective in reducing the emissions from POME in POM by more than 50% of total GHG emissions. Therefore, it is important to ensure that the CPO is produced by POMs equipped with methane capture facilities. Currently, there are only about 10–11% of biodiesel plants that are using the facilities.

The following are conclusions of the study by Traction:

- GHG emissions from plantations and POM contribute 83–95% of total GHG emissions.

- The methane capture facility in POM can reduce about half of the total emissions of POM, which is part of the supply chain.

- The productivity of independent smallholder plantations is lower than company plantations. With productivity level of independent smallholders being 50% lower than that of company plantations, the size of land needed by independent smallholders to produce the same output as company plantations is twice bigger.

- FFB transportation is the main contributor to GHG emissions from independent smallholders.

Suggestions proposed by Traction for the improvement of biodiesel production governance are:

- GHG emission threshold should be set for the use of CPO as feedstock for biodiesel in Indonesia.

- The traceability of FFB is urgently required in the production of CPO-based biodiesel.

- Improvement in the management of FFB distribution to POM is also required to reduce GHG emissions from transportation sector.

- The productivity of independent smallholders needs to be increased.

- Better coordination between LUCF or plantation sector and energy sector is indispensable.

Based on the study, Traction concludes that in order to meet the energy resilience and GHG emission reduction targets as pledged by the Indonesian Government, a good governance of the use of CPO-based biodiesel is an absolute requirement. Moreover, it must be ensured that biodiesel is a clean energy from the upstream to downstream sectors.